Mortise swing door lockset for privacy door (WC) Brass | GSV-Nr. 3401 WCG

5. February 2020

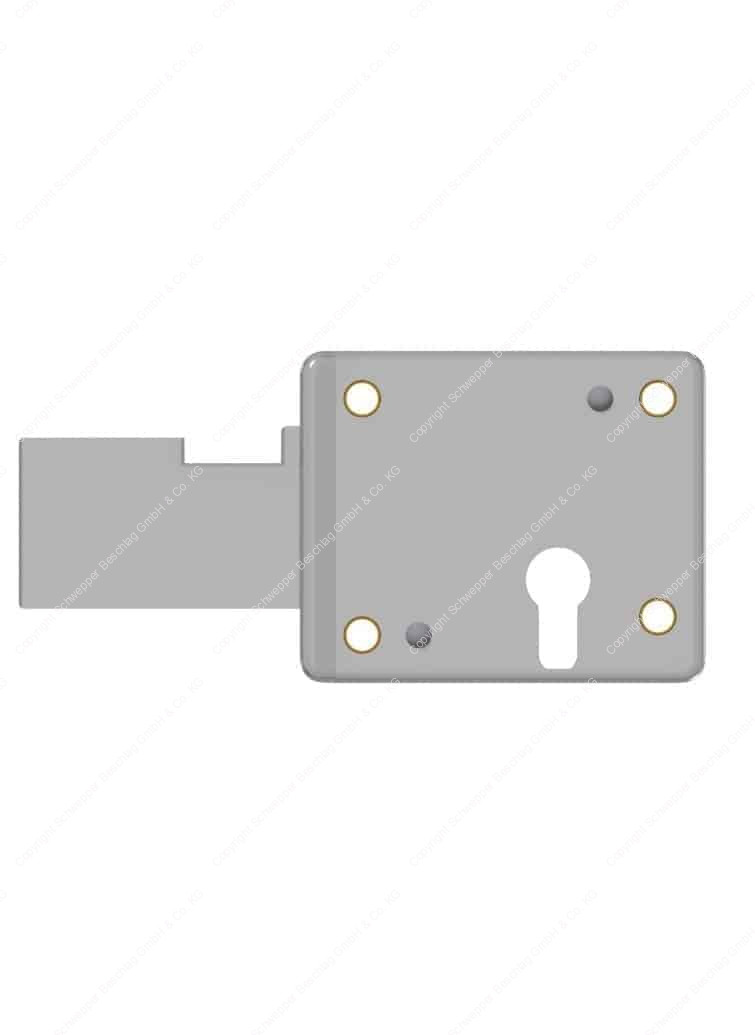

Cabinet lock with cylinder Brass | GSV-No. 3711 Z

17. March 2020Fully integrated service design / manufacturing / customization of lock function

Standard productOur satisfied customer base from the Railway industry:

- Nedtrain

- Neederslands Spoorwegen

- Siemens

- IFE Tebel

- Knorr Bremse AG

- Deutsche Bahn AG

- Mapna

- Bombardier Transportation

- Alstom

- TVER

- Bombardier Transportation Norway AS

- Bode

- BFG

- ULTIMATE Europe Transportation Equipment GmbH

List of renown customer projects:

- ICE2

- ICE3

- Velaro

- Rhealys

- ScotRail

- Morgate

- Metro Berlin

Schwepper offers a full service design and manufacturing of a lock function out of one hand according to submitted specification. The service encompasses the complete process from submission of RFQ to the manufacturing of the product.

Send us Your RFQ with specifications.

The process in detail:

- Feasibility study

- Engineering cost estimation

- Technical Engineering and design processing on customer´s specific construction order

- Preparation and submission of commercial offer

- Order processing on customer´s production order

- Production and product delivery

No stock of the item - will be manufactured after the order is placed.

Schwepper GmbH stands for innovation, precision, and reliability – values we embody in every single project. As a specialist in the development, manufacturing, and customization of individual locking functions, we offer our customers an all-in-one service. Particularly in the demanding rail vehicle industry and related sectors, we have established ourselves as a trusted partner.

From the very first idea through to series-ready delivery, we support our customers with experience, expertise, and dedication. At the beginning, we take the time for a thorough feasibility analysis, precisely assessing customer requirements and specifications. Based on this, we provide a transparent outline of the development effort as well as a realistic estimation of engineering costs. In this way, we create clarity and trust from the start.

In the subsequent design and engineering phase, tailor-made locking solutions are created that not only meet the highest technical standards but are also aligned with the specific needs of our customers. At the same time, we prepare a reliable offer that takes into account project scope, scheduling, and material requirements.

Once commissioned, our engineering and production teams bring the developed concepts to life using state-of-the-art technology and certified quality standards. Thanks to the close integration of development and manufacturing, we ensure that ideas are seamlessly transferred into series production.

Our locking solutions are in use worldwide – for example at Deutsche Bahn AG, Siemens, Alstom, Bombardier, or Knorr-Bremse AG. They have proven themselves in renowned vehicle platforms such as the ICE2, ICE3, Velaro, Talgo 073, or the Berlin Metro.

What sets us apart is the combination of technical excellence, efficient project management, and in-house manufacturing depth. This allows us not only to guarantee short communication paths but also to deliver customized solutions of the highest quality – reliable, innovative, and sustainable.