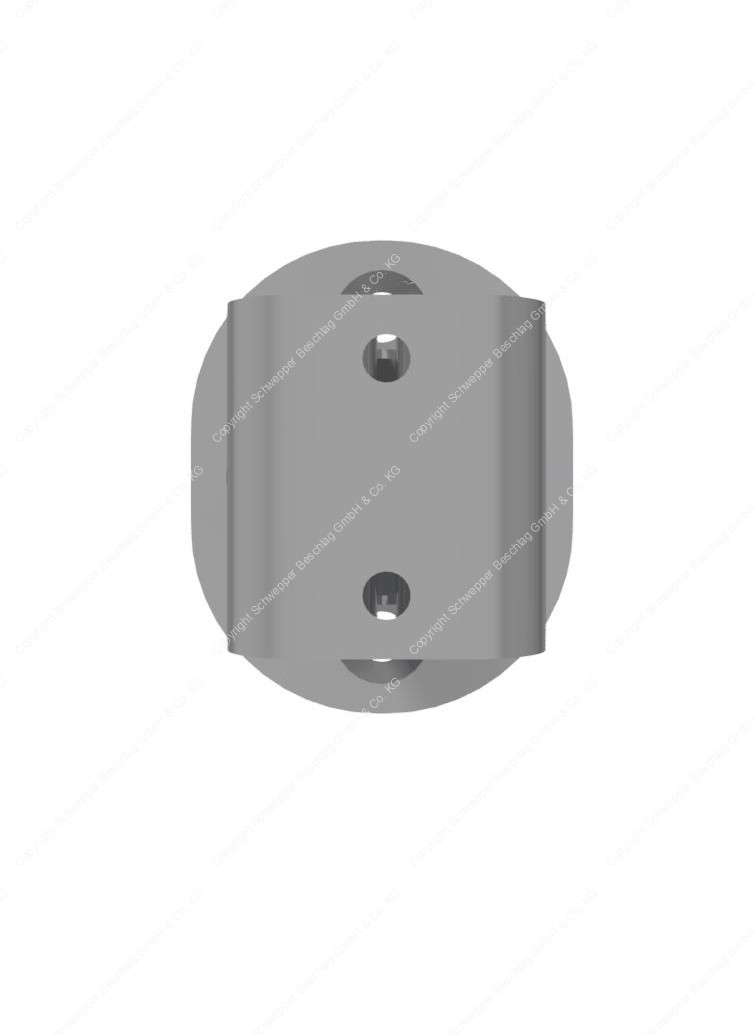

Spring catch with rubber for doors Brass | GSV-No. 5078

7. February 2019

Spring catch Brass | GSV-No. 4078

7. February 2019The spring catch with rubber for doors, GSV-No. 5078 A, is a precision-engineered hardware component designed for reliable latching and secure retention of doors, panels, and access points in residential, commercial, and industrial applications. Constructed from high-quality brass, the spring catch provides excellent corrosion resistance, mechanical strength, and long-term durability. Brass is particularly well-suited for door hardware due to its dimensional stability, wear resistance, and ability to maintain precise operation even under frequent or heavy use, ensuring consistent performance over extended periods.

This spring catch features an integrated rubber element that significantly enhances its functionality. The rubber serves as a cushioning and noise-dampening layer, reducing the impact and vibration when the door closes. This not only minimizes operational noise but also protects both the door and the catch from premature wear, scratches, or damage. The combination of brass and rubber allows for secure engagement while providing smooth and controlled closing action, improving overall usability and comfort.

The spring mechanism is precisely calibrated to ensure the catch automatically engages when the door is closed. This provides reliable self-latching, preventing accidental openings caused by wind, vibrations, or external forces. The component is designed for secure and stable mounting on doors or frames, ensuring proper alignment and long-term reliability.

The GSV-No. 5078 A spring catch with rubber combines high-quality brass, precision spring mechanics, and a resilient rubber buffer to deliver a technically advanced, durable, and reliable solution. It ensures secure engagement, reduced noise, smooth operation, and long-lasting performance, making it an ideal choice for diverse door applications where safety, functionality, and longevity are critical.

Current general delivery dates subject to the usual reservations::

Brass:

• The general delivery time for products in brass satin chromed is currently 6-8 weeks

• The general delivery time for products in brass polished / brass polished chromed is currently 8-10 weeks

Stainless Steel:

• The general delivery time for products in stainless steel is currently 6 weeks

• The general delivery time for products in stainless steel polished / fine grind is currently 6-8 weeks

Aluminum:

• The general delivery time for products in Aluminum silver andodized is currently 6 weeks

• The general delivery time for products in Aluminum powder coated is currently 6-8 weeks

Special/project products:

No standard delivery time, as components are only made to order. In each case by individual arrangement

| Weight | N/A |

|---|---|

| HS-Code | |

| Product class | |

| Product type | |

| Area of product installation | |

| Sales unit | |

| DIN |

Note on express dispatch | 24 delivery service

Note on express dispatch | 24 delivery service Each item with a stock quantity can be dispatched within 24 hours. The surcharge for the 24h delivery service is 5%.

Our products do not contain the following chemical hazardous substances:

Asbestos

Polychlorinated biphenyls (PCBs)

Chlorofluorocarbons (CFCs)

Halons

Carbon tetrachloride

1-1-1-Trichloroethane

Hydrochlorofluorocarbons

Hydrobromofluorocarbons

Methyl bromide

Bromochloromethane

Anti-fouling systems containing organotin compounds as a biocide

Cadmium and cadmium compounds

Hexavalent chromium and hexavalent chromium compounds

Lead and lead compounds larger 3%

Mercury and mercury compounds

Polybrominated biphenyl (PBBs)

Polybrominated dephenyl ethers (PBDEs)

Polychloronaphthalenes (Cl >= 3)

Radioactive substances

Certain shortchain chlorinated paraffins

Perfluorooctane sulfonic acid (PFOS)

Brominated Flame Retardant (HBCDD)