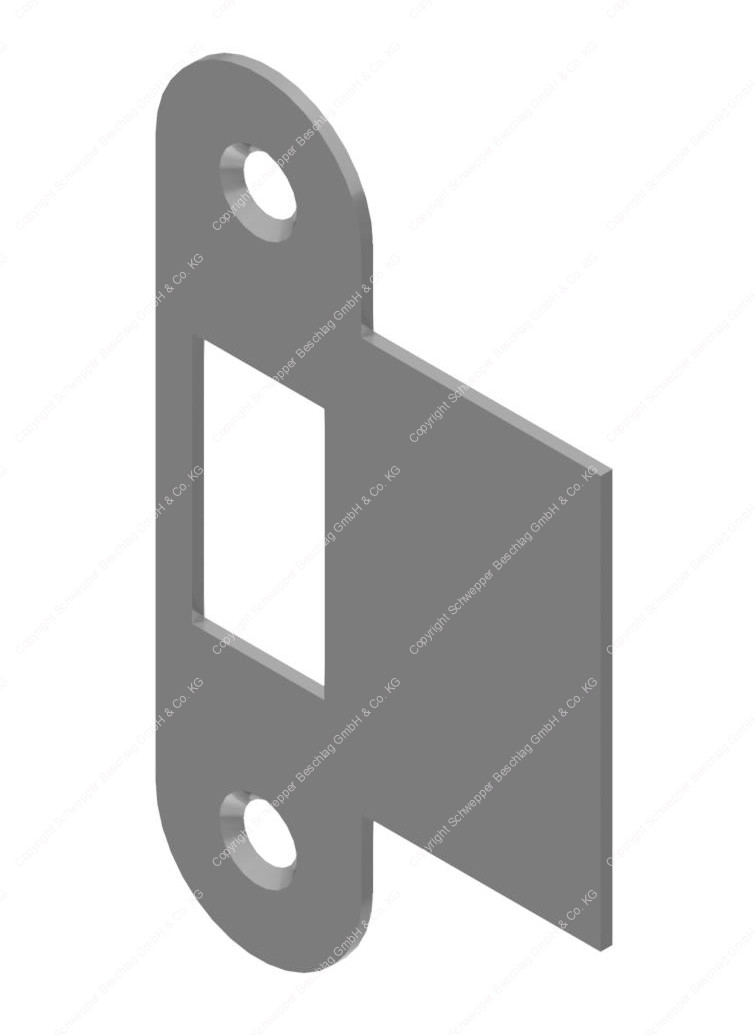

Strike Box Brass | GSV-No. 3225

2. February 2019

Mortise sliding door lock for bit / skeleton key backset 55mm Brass | GSV-No. 3248

2. February 2019The strike plate for midsized rim locks or small mortise latch locks, available in brass or alternatively in stainless steel (304), GSV-No. 3231, is a precision-engineered component designed to ensure reliable and secure engagement of lock mechanisms in doors, cabinets, and furniture. Serving as the receiving element for the latch or deadbolt, the strike plate provides stable closure, proper alignment, and smooth operation of the locking system. Its precise design prevents misalignment, rattling, or unintended movement of the bolt or latch, ensuring consistent and long-term functionality.

Manufactured from high-quality brass, the strike plate combines excellent mechanical strength, durability, and corrosion resistance. Brass ensures that the component maintains its shape and structural integrity even under frequent operation, while protecting the lock mechanism and surrounding surfaces from wear, abrasion, or damage. For applications requiring enhanced environmental resistance, the stainless steel (304) version provides superior corrosion and chemical resistance, making it suitable for humid, exterior, or industrial settings where long-term durability is critical.

The strike plate is precisely machined to ensure the latch or bolt of the lock engages securely and smoothly, preventing unwanted play or binding. Its robust construction maintains dimensional stability and mechanical integrity, supporting the reliable operation of both the lock and the door or furniture structure.

GSV-No. 3231 strike plate represents a technically advanced, versatile, and durable solution for both midsized rim locks and small mortise latch locks. Its combination of high-quality materials, precision engineering, and reliable performance makes it an ideal choice for professional installations, furniture manufacturing, and repair applications where security, longevity, and functional reliability are essential.

Current general delivery dates subject to the usual reservations::

Brass:

• The general delivery time for products in brass satin chromed is currently 6-8 weeks

• The general delivery time for products in brass polished / brass polished chromed is currently 8-10 weeks

Stainless Steel:

• The general delivery time for products in stainless steel is currently 6 weeks

• The general delivery time for products in stainless steel polished / fine grind is currently 6-8 weeks

Aluminum:

• The general delivery time for products in Aluminum silver andodized is currently 6 weeks

• The general delivery time for products in Aluminum powder coated is currently 6-8 weeks

Special/project products:

No standard delivery time, as components are only made to order. In each case by individual arrangement

| Weight | N/A |

|---|---|

| Product class | |

| HS-Code | |

| Product type | |

| Area of product installation | |

| Sales unit | |

| DIN |

Note on express dispatch | 24 delivery service

Note on express dispatch | 24 delivery service Each item with a stock quantity can be dispatched within 24 hours. The surcharge for the 24h delivery service is 5%.

Our products do not contain the following chemical hazardous substances:

Asbestos

Polychlorinated biphenyls (PCBs)

Chlorofluorocarbons (CFCs)

Halons

Carbon tetrachloride

1-1-1-Trichloroethane

Hydrochlorofluorocarbons

Hydrobromofluorocarbons

Methyl bromide

Bromochloromethane

Anti-fouling systems containing organotin compounds as a biocide

Cadmium and cadmium compounds

Hexavalent chromium and hexavalent chromium compounds

Lead and lead compounds larger 3%

Mercury and mercury compounds

Polybrominated biphenyl (PBBs)

Polybrominated dephenyl ethers (PBDEs)

Polychloronaphthalenes (Cl >= 3)

Radioactive substances

Certain shortchain chlorinated paraffins

Perfluorooctane sulfonic acid (PFOS)

Brominated Flame Retardant (HBCDD)

The hand of door for mortise locks is defined as:

if the door is closed and the hinges are visible on the right/left, then the door is right/left hand. The door is therefore hinged on the right/left and according by definition of DIN right/left.

Or: if you grasp the handle with your right hand and latch and deadbolt show to the left, then it is right hand. If you grasp the handle with your left hand latch and deadbolt show to the right, it is a left hand.

Rim locks

The hand of door for rim locks is defined as:

if the door is closed and the hinges are visible on the right/left, then the door is right /left hand. The door is therefore hinged on the right/left and according to the definition DIN “right/left".

In addition to the designation “left” and “right”, it is to be indicated whether the locks are intended for inward or outward opening doors.

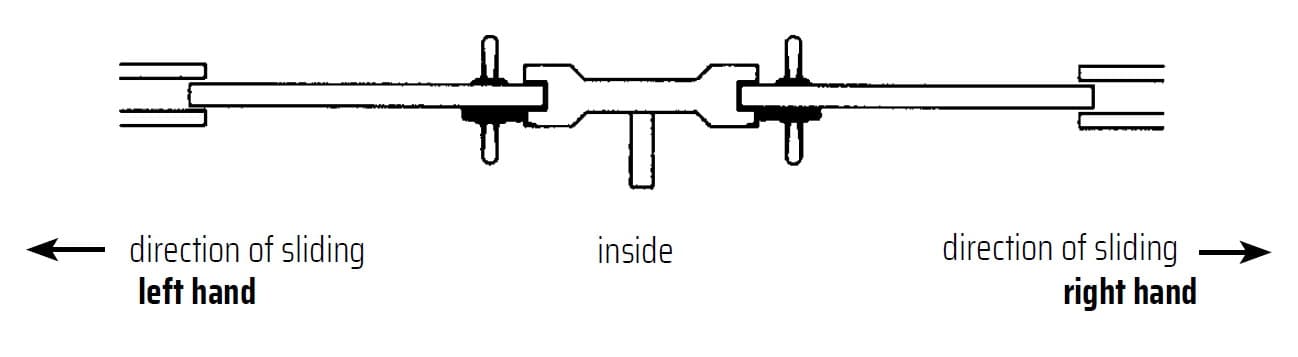

Sliding door mortises

The hand of door for sliding door mortises is the same for right and left. Sliding rim door locks different for left and right doors.

When ordering, always indicate “left” or “right”.

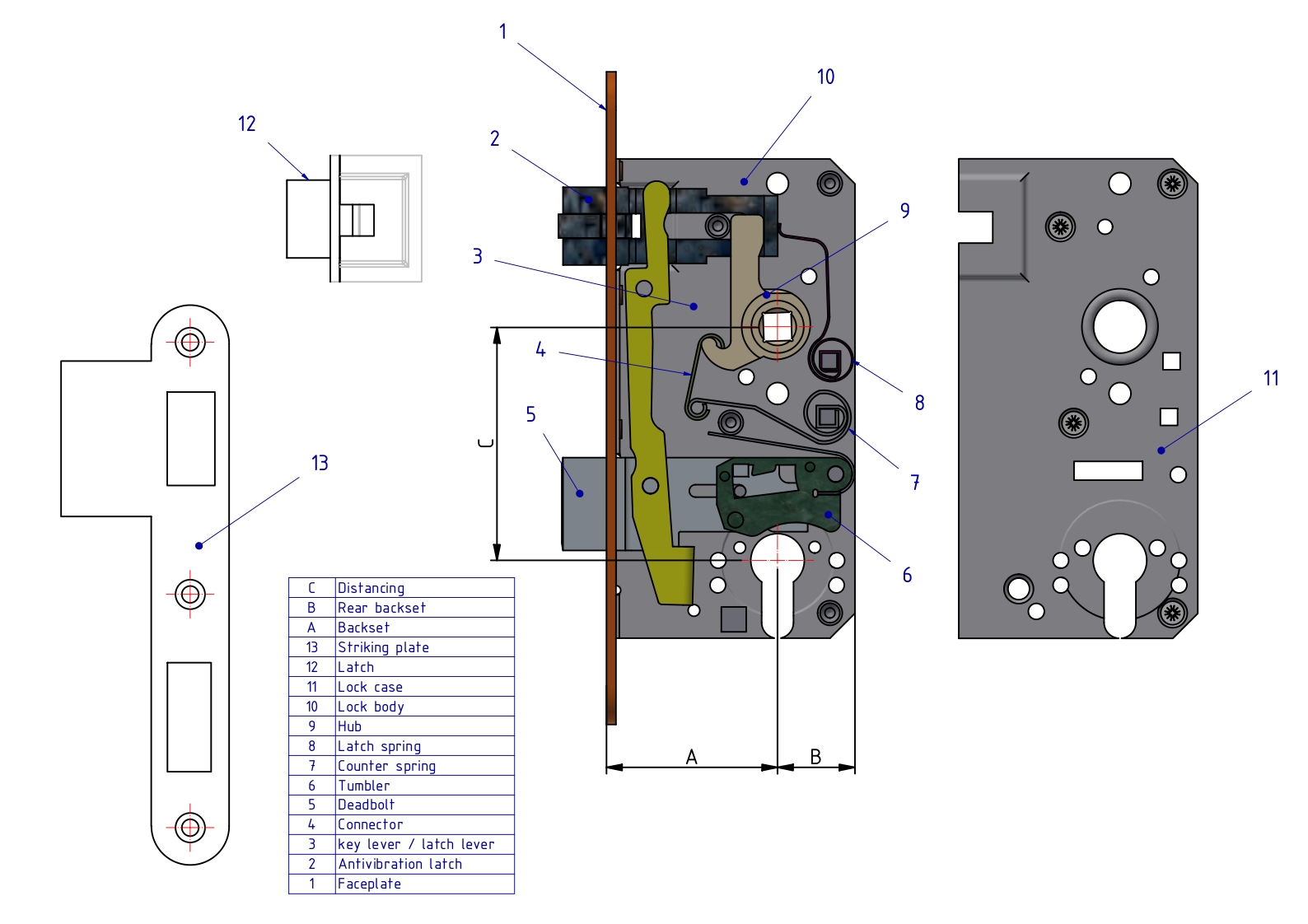

| Latch

The lock latch keeps the door shut. In order to open the door, it must be retracted. |

| Type of latch design | Illustration |

| single latch |  |

| anti-vibration or three-piece latch |  |

| rolling latch adjustable |  |

| POM-latch for strike dampening |  |

| Deadbolt

The deadbolt regulates the access rights through the turning motion of the cylinder by key. The deadbolt is being driven out or retracted through the turning motion. |

|

| Faceplate

The faceplate is the visible part of the lock case. The faceplate, the latch and the deadbolt are the only visible parts of a mortise. |

|

Handle hub

The handle hub takes the square spindle of the handle in order to retract the latch inside the lock through the turning motion of the same. This process allows the opening of the door. The shipbuilding norm specifies a 9mm square with a 2° incline. Schwepper supplies also with 8mm square, special contour or 0° incline on request. |

|

WC-/privacy hub

The WC hub takes the square spindle of the olive or thumb turn, that retracts or drives out the deadbolt from the inside - analogue to the turning motion of the cylinder. The shipbuilding norm specifies a 7mm square. Schwepper supplies also with 8mm square on request. |

|

| Dimension | Illustration | |

| Backset

The backset is the distance from the front edge of the faceplate to the center of the cylinder hole respectively handle hub square. The rear backset behind the center line remains always 27mm. |

|

|

| Distancing

The distancing is the dimension from the center of the handel hub and the center of the hole for profile cylinder / privacy (WC) / key. The industry standard in shipbuilding is 75mm. |

|

|

| Latch protrusion

The latch protrudes according to the industrial DIN standard in shibuilding 14mm. Other technical standards for latch protrusion are: 16 mm according to DOT (Department of Transportation) 19 mm according to USCG (US Coast Guard) |

|

|