Friction plate Brass | GSV-No. 3152

7. February 2019

Latch for inward-faced installation on hatches and flaps Brass | GSV-No. 3153

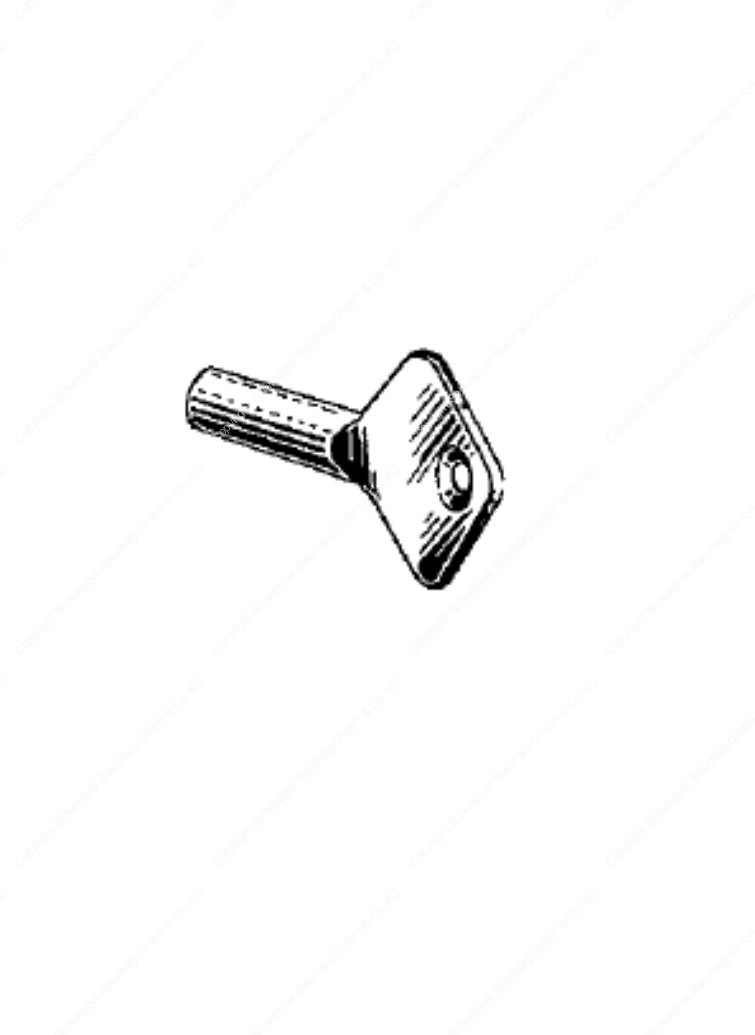

7. February 2019The 9 mm triangular spanner key, GSV-No. 4529 B, is a precision-engineered tool specifically designed for operating triangular lock mechanisms in hatches, flaps, cabinets, and similar applications. Constructed from high-quality brass, the spanner key offers excellent corrosion resistance, mechanical strength, and long-term durability. Brass is particularly suitable for key tools due to its wear resistance, robustness, and ability to maintain dimensional stability even under frequent use. Its smooth surface finish also provides a comfortable tactile experience and an aesthetically pleasing appearance suitable for both visible and concealed applications.

The key features a 9 mm triangular cross-section, precisely matching the corresponding triangular keyhole of compatible latches. This exact fit ensures controlled and efficient force transmission, allowing the lock mechanism to be engaged or disengaged smoothly and reliably. The precise geometry minimizes the risk of slippage and reduces wear on both the key and the lock, maintaining operational reliability over time.

Ergonomically designed, the spanner key allows for comfortable handling and precise control, even in confined installation spaces or when repeated operation is required. Its robust brass construction prevents deformation or fatigue, ensuring consistent performance throughout its service life.

The triangular spanner key GSV-No. 4529 B is a technically advanced, reliable, and durable tool, providing secure, accurate, and efficient operation of triangular locking mechanisms. It ensures safe and precise manipulation of latches, contributing to the long-term functionality and security of hatches, flaps, and access panels across residential, commercial, and light industrial environments.

Current general delivery dates subject to the usual reservations::

Brass:

• The general delivery time for products in brass satin chromed is currently 6-8 weeks

• The general delivery time for products in brass polished / brass polished chromed is currently 8-10 weeks

Stainless Steel:

• The general delivery time for products in stainless steel is currently 6 weeks

• The general delivery time for products in stainless steel polished / fine grind is currently 6-8 weeks

Aluminum:

• The general delivery time for products in Aluminum silver andodized is currently 6 weeks

• The general delivery time for products in Aluminum powder coated is currently 6-8 weeks

Special/project products:

No standard delivery time, as components are only made to order. In each case by individual arrangement

| Weight | N/A |

|---|---|

| HS-Code | |

| Product type | Cabinet furniture harwdare, Latches, Special products for the accomodation area |

| Area of product installation | |

| Sales unit | |

| Product class |

Note on express dispatch | 24 delivery service

Note on express dispatch | 24 delivery service Each item with a stock quantity can be dispatched within 24 hours. The surcharge for the 24h delivery service is 5%.

Our products do not contain the following chemical hazardous substances:

Asbestos

Polychlorinated biphenyls (PCBs)

Chlorofluorocarbons (CFCs)

Halons

Carbon tetrachloride

1-1-1-Trichloroethane

Hydrochlorofluorocarbons

Hydrobromofluorocarbons

Methyl bromide

Bromochloromethane

Anti-fouling systems containing organotin compounds as a biocide

Cadmium and cadmium compounds

Hexavalent chromium and hexavalent chromium compounds

Lead and lead compounds larger 3%

Mercury and mercury compounds

Polybrominated biphenyl (PBBs)

Polybrominated dephenyl ethers (PBDEs)

Polychloronaphthalenes (Cl >= 3)

Radioactive substances

Certain shortchain chlorinated paraffins

Perfluorooctane sulfonic acid (PFOS)

Brominated Flame Retardant (HBCDD)