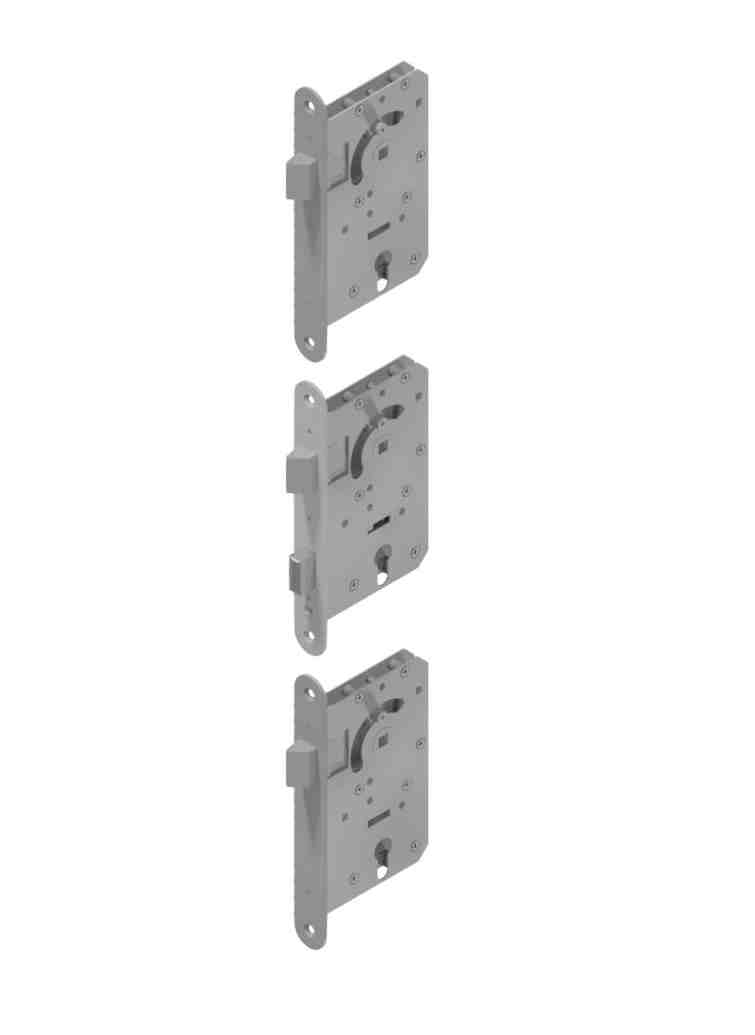

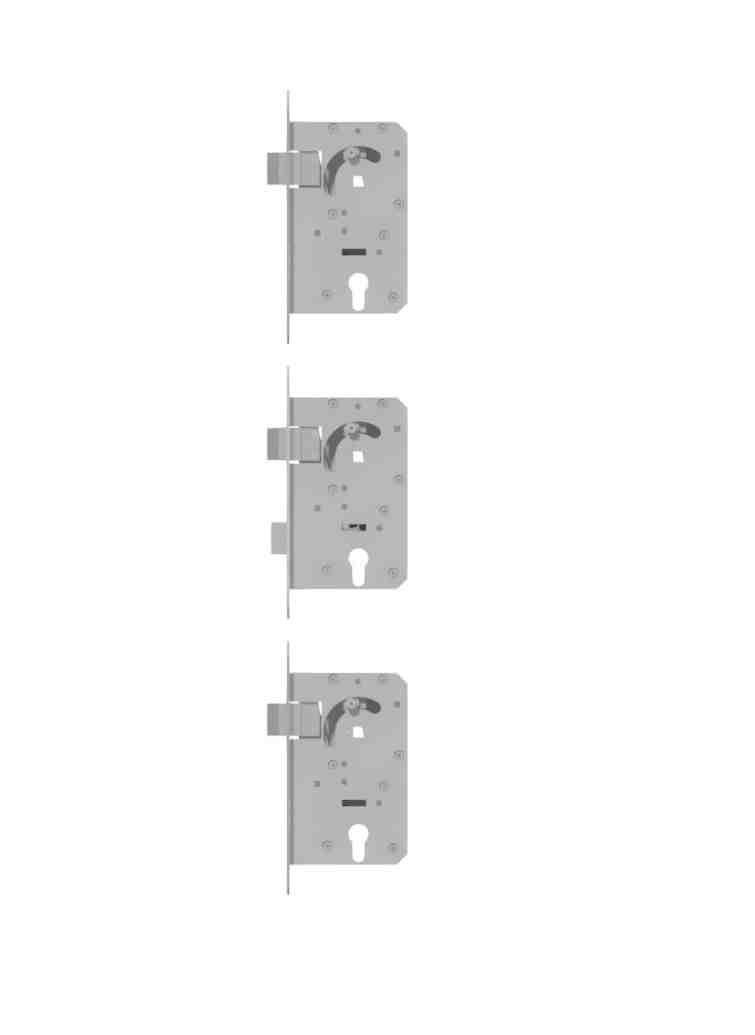

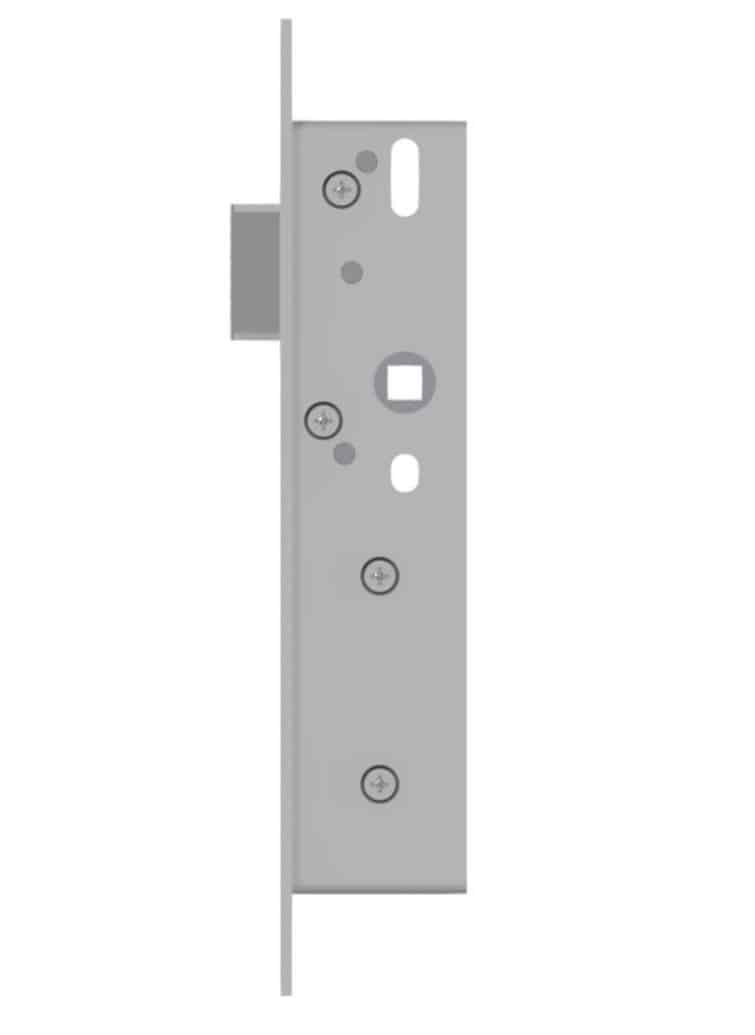

Mortise swing door lockset for privacy door (WC) Brass | GSV-Nr. 3401 WCG

5. Februar 2020

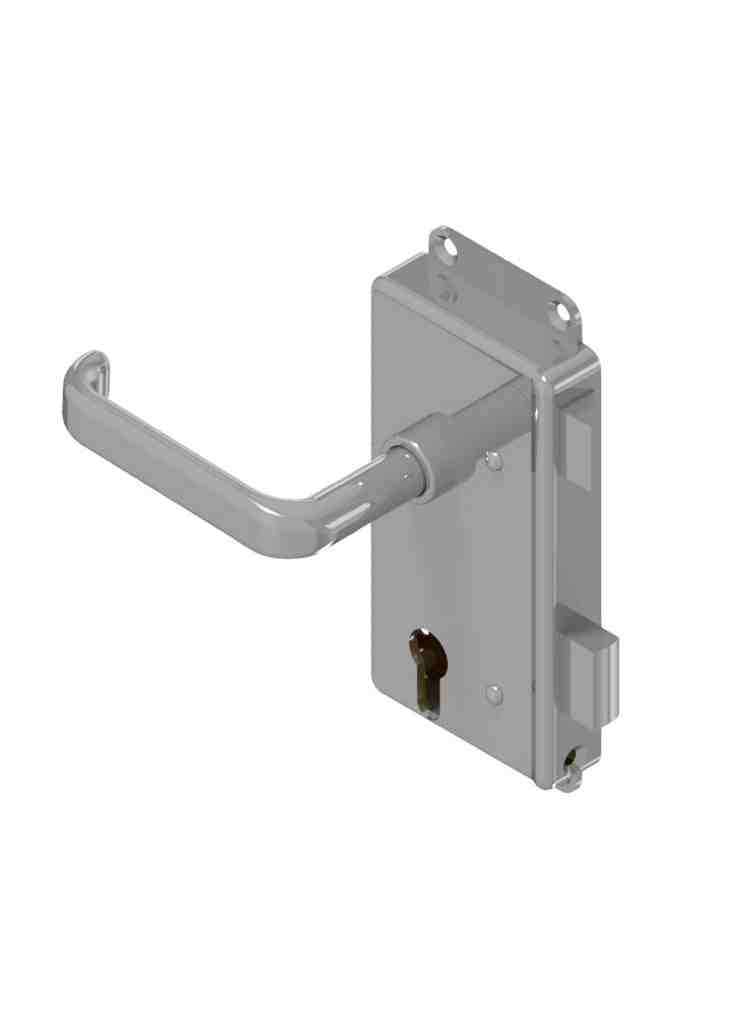

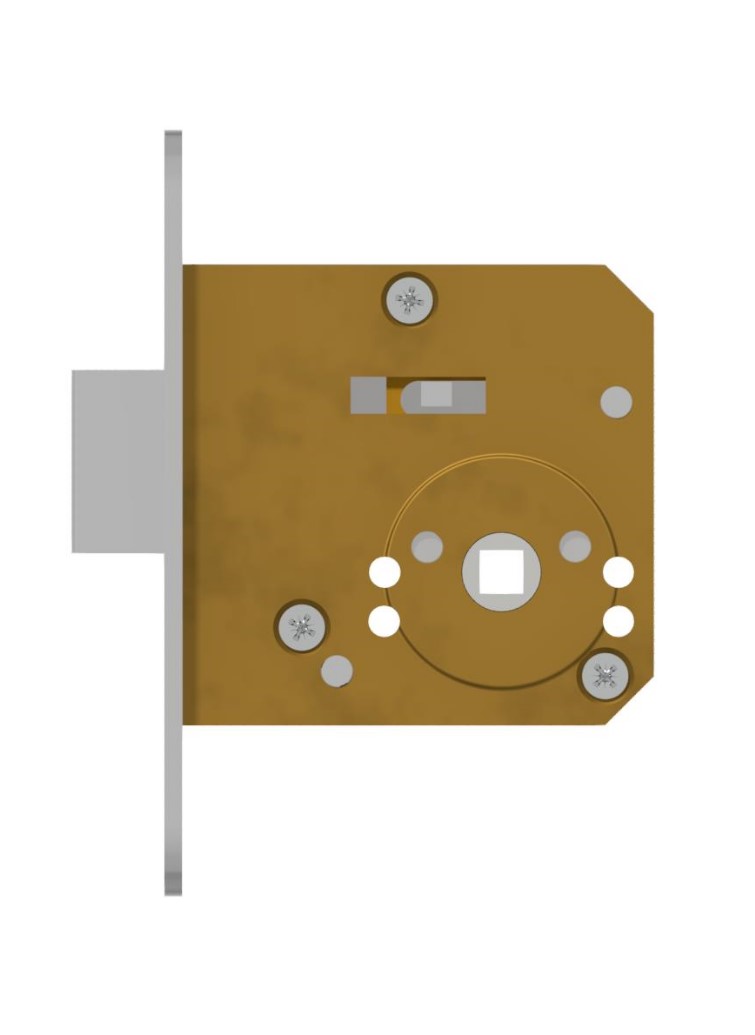

Cabinet lock with cylinder Brass | GSV-No. 3711 Z

17. März 2020Fully integrated service design / manufacturing / customization of lock function

Standard productOur satisfied customer base from the Railway industry:

- Nedtrain

- Neederslands Spoorwegen

- Siemens

- IFE Tebel

- Knorr Bremse AG

- Deutsche Bahn AG

- Mapna

- Bombardier Transportation

- Alstom

- TVER

- Bombardier Transportation Norway AS

- Bode

- BFG

- ULTIMATE Europe Transportation Equipment GmbH

List of renown customer projects:

- ICE2

- ICE3

- Velaro

- Rhealys

- ScotRail

- Morgate

- Metro Berlin

Schwepper offers a full service design and manufacturing of a lock function out of one hand according to submitted specification. The service encompasses the complete process from submission of RFQ to the manufacturing of the product.

Send us Your RFQ with specifications.

The process in detail:

- Feasibility study

- Engineering cost estimation

- Technical Engineering and design processing on customer´s specific construction order

- Preparation and submission of commercial offer

- Order processing on customer´s production order

- Production and product delivery

No stock of the item - will be manufactured after the order is placed.

Schwepper GmbH offers comprehensive development, manufacturing, and customization of individual locking mechanisms from a single source – specifically designed for use in rail vehicles and related industrial sectors. This all-in-one service covers every stage of the project, from the initial inquiry to the delivery of series-ready products. Clients benefit from our many years of experience and high level of in-house production.

The process begins with a detailed feasibility analysis based on the specifications and requirements provided by the customer. Subsequently, the engineering costs are estimated and the development effort is presented transparently. The next step is the technical engineering and design process, during which a precise locking concept is developed in accordance with relevant standards and customer requirements. At the same time, a concrete offer is prepared, taking into account the project scope, deadlines, and material requirements.

Upon commissioning, the technical implementation begins. Our engineering and production teams work closely together to ensure a seamless transition of design data into series production. Manufacturing takes place in modern facilities and follows certified quality standards.

Our locking solutions are used worldwide. Our project clients include, among others, Deutsche Bahn AG, Siemens, Alstom, Bombardier, Knorr-Bremse AG, and other well-known companies. Schwepper locking systems have been successfully integrated into vehicle platforms such as the ICE2, ICE3, Velaro, Talgo 073, and Berlin Metro.

By combining technical expertise, project management, and in-house manufacturing, we ensure short communication paths, high quality, and customized solutions.