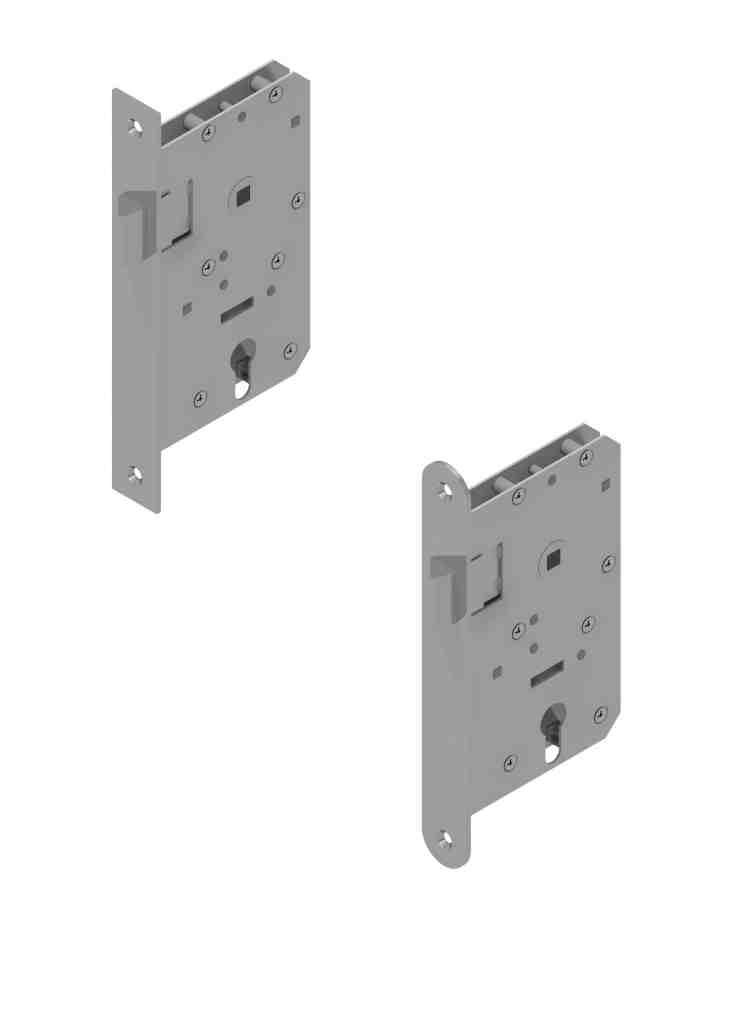

Mortise latch lock with wedge latch for doors with strong sealing Stainless steel | GSV-No. 9105 F

28. August 2019

Door stay | door limiter for heavy glass doors Stainless steel | GSV-No. 5820 GM

3. September 2019Long plate without key hole

GSV-No. 9105 BF

stainless steel brushed

through fixing bolts

stainless steel

| Weight | N/A |

|---|---|

| Product class | |

| HS-Code | |

| Sales unit |

General note: the general delivery times as stated below can deviate in certain cases due of supply shortages!

Brass:

• The general delivery time for products in brass satin chromed is currently 6 weeks

• The general delivery time for products in brass polished / brass polished chromed is currently 8 weeks

Stainless Steel:

• The general delivery time for products in stainless steel is currently 4 weeks

• The general delivery time for products in stainless steel polished / fine grind is currently 6 weeks

Aluminum:

• The general delivery time for products in Aluminum silver andodized is currently 4-6 weeks

• The general delivery time for products in Aluminum powder coated is currently 6-8 weeks

QR Code

What are the general handings of a door?

Answer: Mortises

The hand of door for mortise locks is defined as:

if the door is closed and the hinges are visible on the right/left, then the door is right/left hand. The door is therefore hinged on the right/left and according by definition of DIN right/left.

Or: if you grasp the handle with your right hand and latch and deadbolt show to the left, then it is right hand. If you grasp the handle with your left hand latch and deadbolt show to the right, it is a left hand.

Rim locks

The hand of door for rim locks is defined as:

if the door is closed and the hinges are visible on the right/left, then the door is right /left hand. The door is therefore hinged on the right/left and according to the definition DIN “right/left".

In addition to the designation “left” and “right”, it is to be indicated whether the locks are intended for inward or outward opening doors.

Sliding door mortises

The hand of door for sliding door mortises is the same for right and left. Sliding rim door locks different for left and right doors.

When ordering, always indicate “left” or “right”.

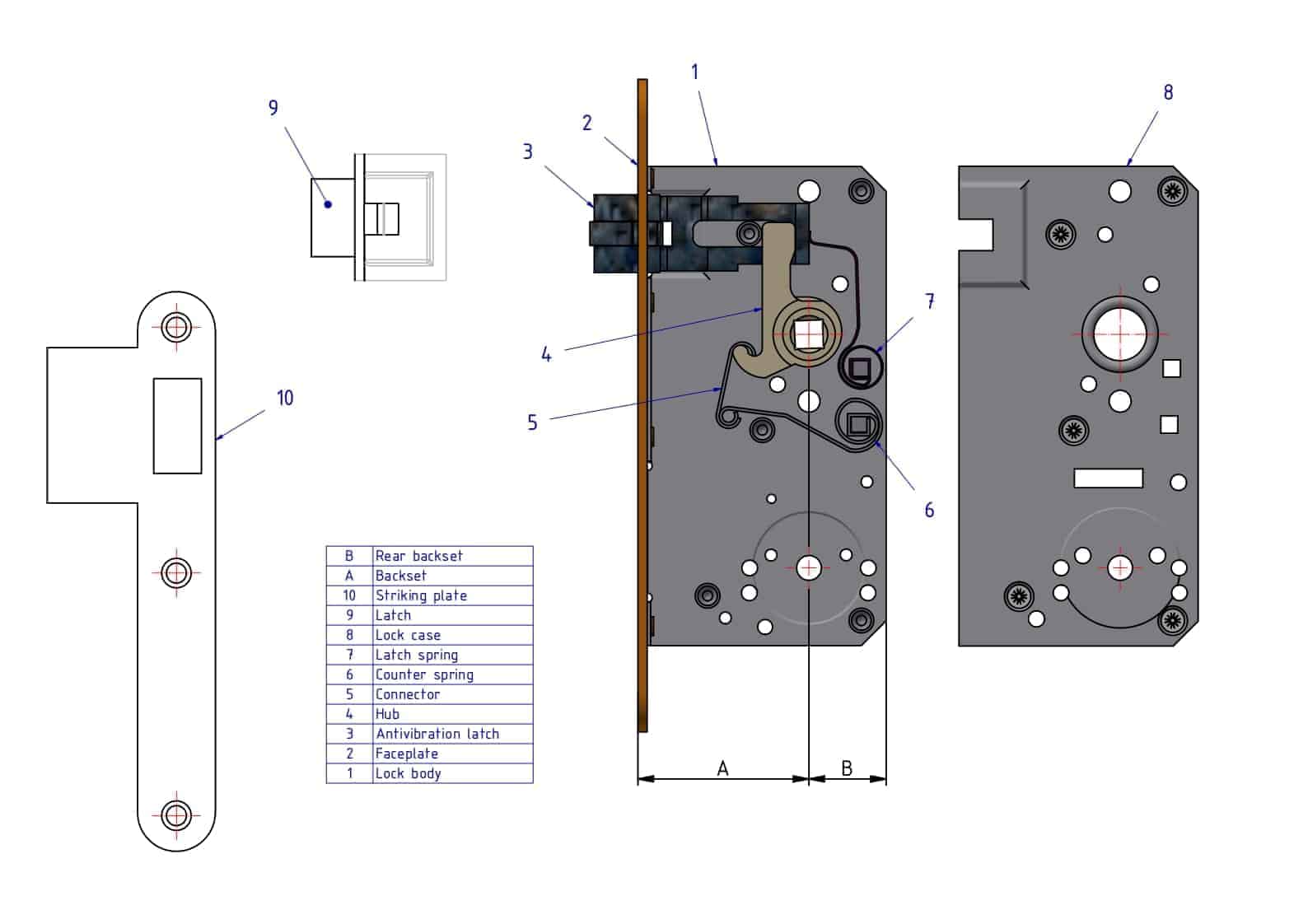

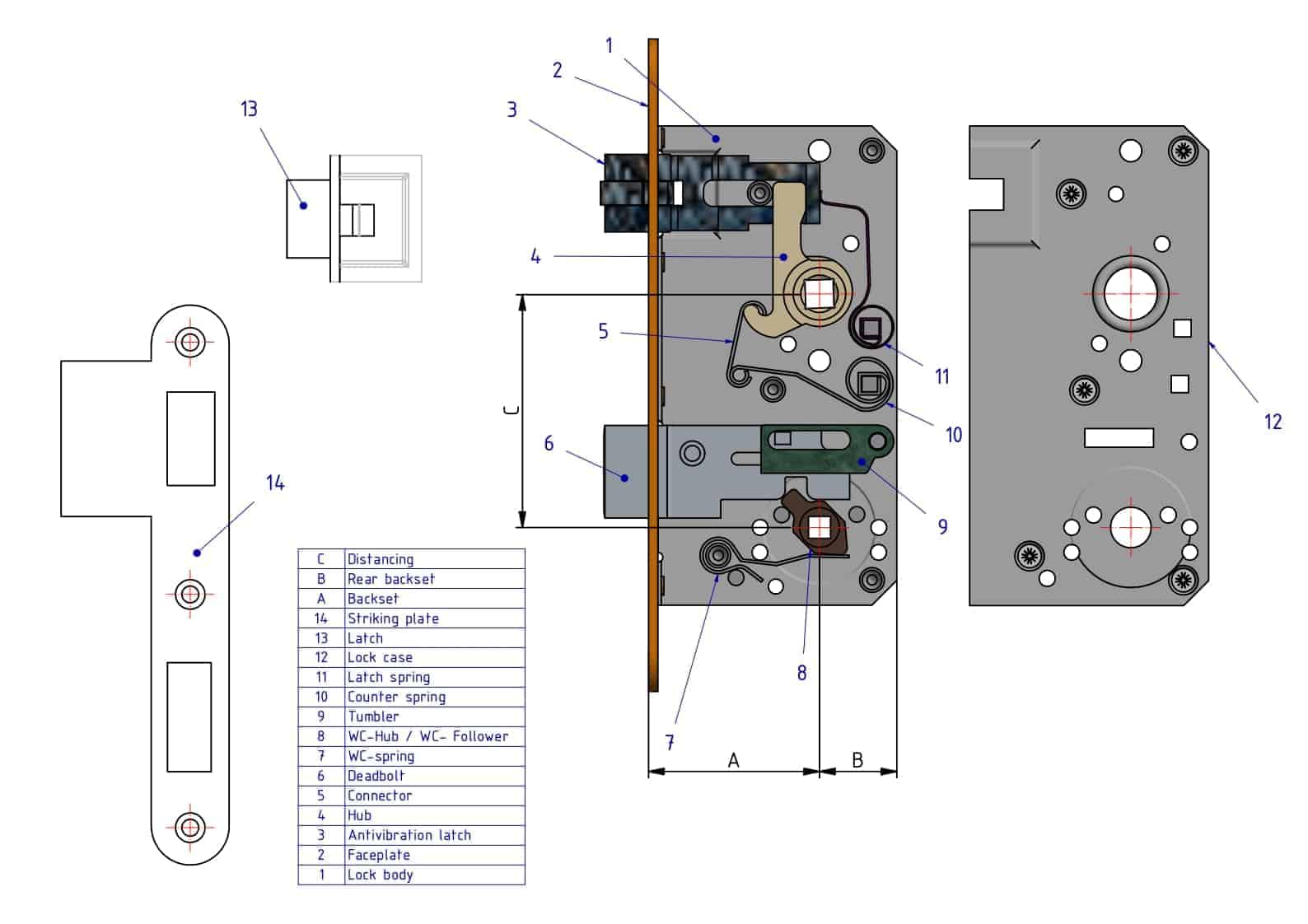

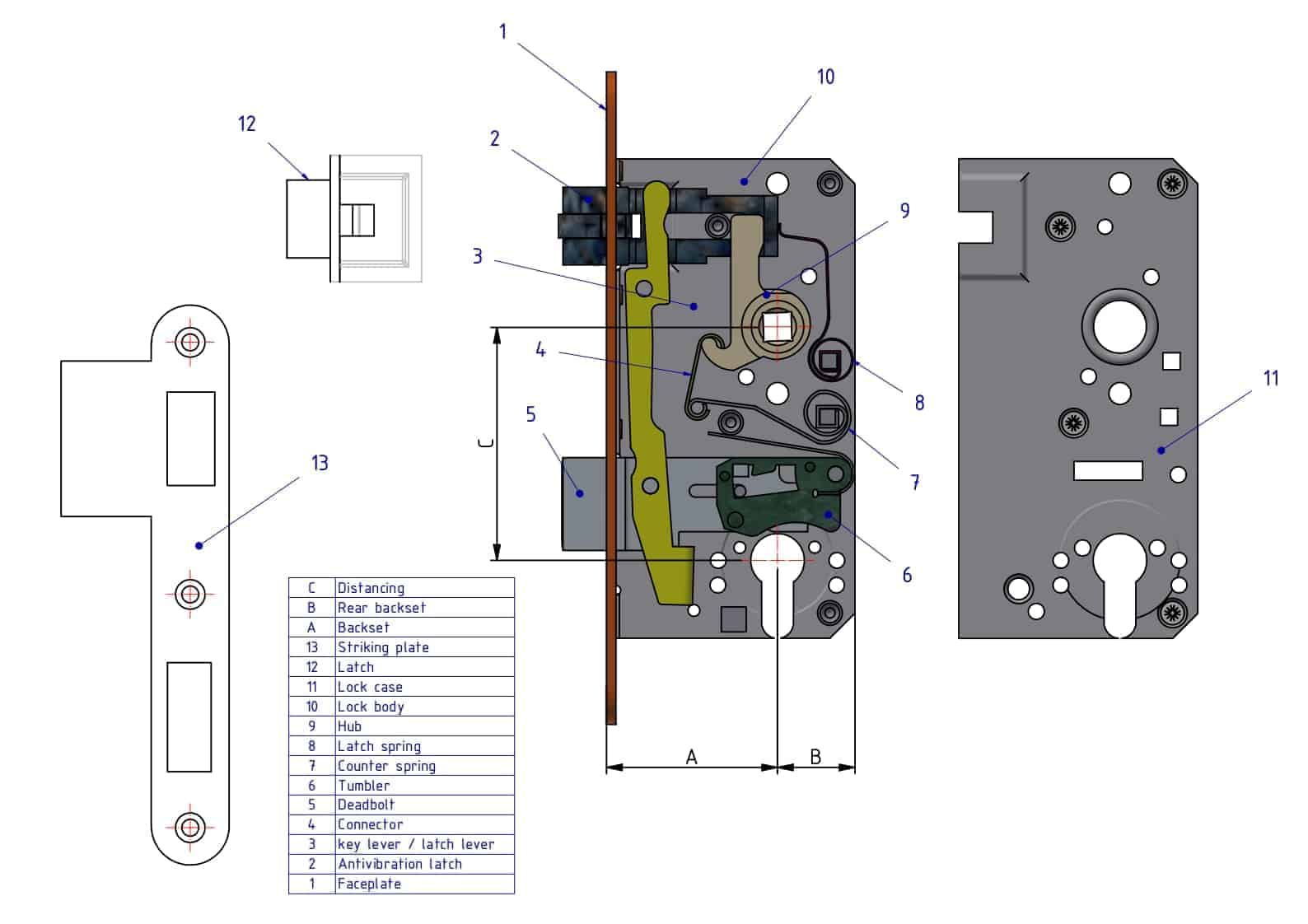

What are the essential components of a lock?

Answer:

| Latch

The lock latch keeps the door shut. In order to open the door, it must be retracted. |

| Type of latch design | Illustration |

| single latch |  |

| anti-vibration or three-piece latch |  |

| rolling latch adjustable |  |

| POM-latch for strike dampening |  |

| Deadbolt

The deadbolt regulates the access rights through the turning motion of the cylinder by key. The deadbolt is being driven out or retracted through the turning motion. |

|

| Faceplate

The faceplate is the visible part of the lock case. The faceplate, the latch and the deadbolt are the only visible parts of a mortise. |

|

Handle hub

The handle hub takes the square spindle of the handle in order to retract the latch inside the lock through the turning motion of the same. This process allows the opening of the door. The shipbuilding norm specifies a 9mm square with a 2° incline. Schwepper supplies also with 8mm square, special contour or 0° incline on request. |

|

WC-/privacy hub

The WC hub takes the square spindle of the olive or thumb turn, that retracts or drives out the deadbolt from the inside - analogue to the turning motion of the cylinder. The shipbuilding norm specifies a 7mm square. Schwepper supplies also with 8mm square on request. |

|

What are the essential dimensions of a lock?

Answer:

| Dimension | Illustration | |

| Backset

The backset is the distance from the front edge of the faceplate to the center of the cylinder hole respectively handle hub square. The rear backset behind the center line remains always 27mm. |

|

|

| Distancing

The distancing is the dimension from the center of the handel hub and the center of the hole for profile cylinder / privacy (WC) / key. The industry standard in shipbuilding is 75mm. |

|

|

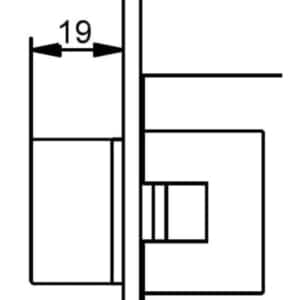

| Latch protrusion

The latch protrudes according to the industrial DIN standard in shibuilding 14mm. Other technical standards for latch protrusion are: 16 mm according to DOT (Department of Transportation) 19 mm according to USCG (US Coast Guard) |

|

|